The (white) chip in the board-centre is a Neo-7M-000 from uBlox. (There are several other chips in the Neo-family that differ mostly by their type of oscillator. The Neo-7M uses a straight crystal whilst the 7N has an in-built temperature controlled oscillator, for example).

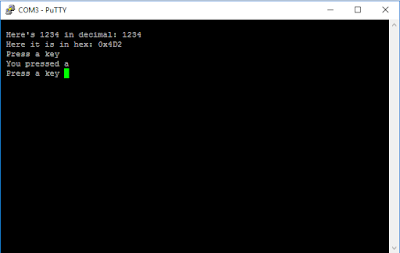

uBlox have free software on their website that allows you to talk to the GPS module from Windows through USB when you use a USB-to-TTL converter (mine's the red 'CP102' module at the left of the photo; A couple of $'s on eBay).

It's super-satisfying when you connect things up for the first time and a world-map appears showing you a bunch of orbiting GPS satellites you've locked on to.

Naturally you can read GPS time and location data from your Neo, but (following an idea from the excellent Scullcom hobby electronics site) I was keen to get my hands on a GPS-accurate frequency-source.

This means means soldering a wire (here yellow) to one terminal of a surface-mount resistor on the PCB. Photo 3 below shows the detail

The default setting of the Neo is to spit out a 1Hz square wave on the yellow wire, but the software (under the View/Configuration View/TP5 menu) allows you to change this. I captured the oscilloscope trace below with my Neo output set to a 1MHz square wave

The significance of all this is that, for a few $'s, I now have a GPS ('atomic clock') accurate frequency source! This opens the door to all sorts of fun stuff that relies on an ability to very accurately time events: A homemade experiment to measure the gravitational constant by very accurately timing swings of a pendulum say - or a dozen other things.

If you've thoughts about that or any of the other stuff on this blog here I'd love to hear your suggestions.